CSS Drop Down Menu by PureCSSMenu.com

CSS Drop Down Menu by PureCSSMenu.com

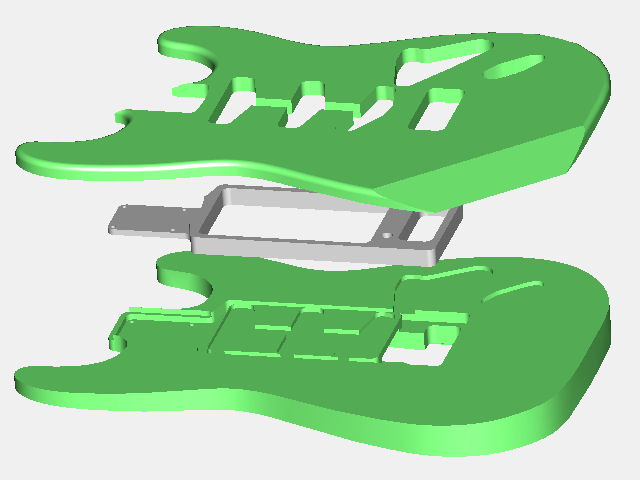

Below are exploded CAD drawings of a Sedona body, aluminum block, and top.

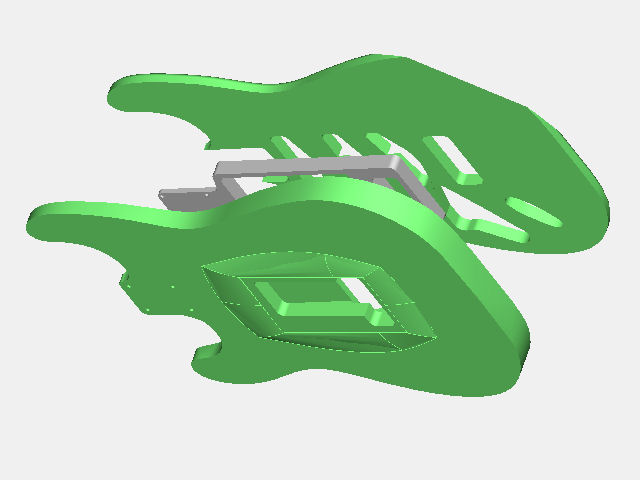

Since the wedge shaped body is thinner, to fit a standard size tremolo block that normally fits a 1.75" thick body, the backside of a Sedona has a bulge, or "archtop"

At its thickest point, the bulge only protrudes about 1/4" from the back of the body.

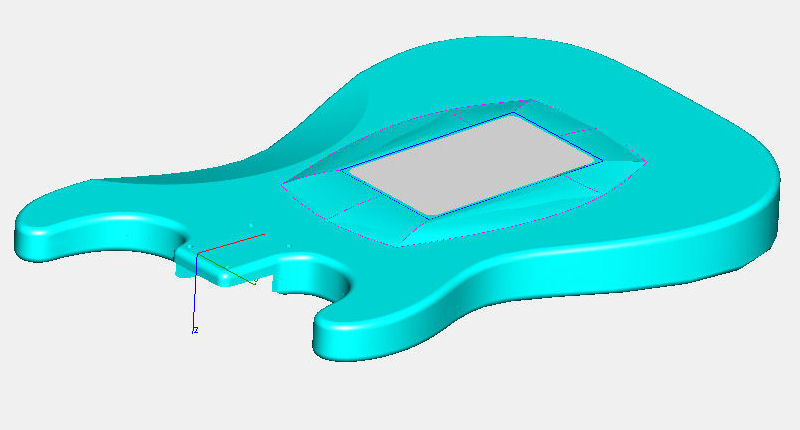

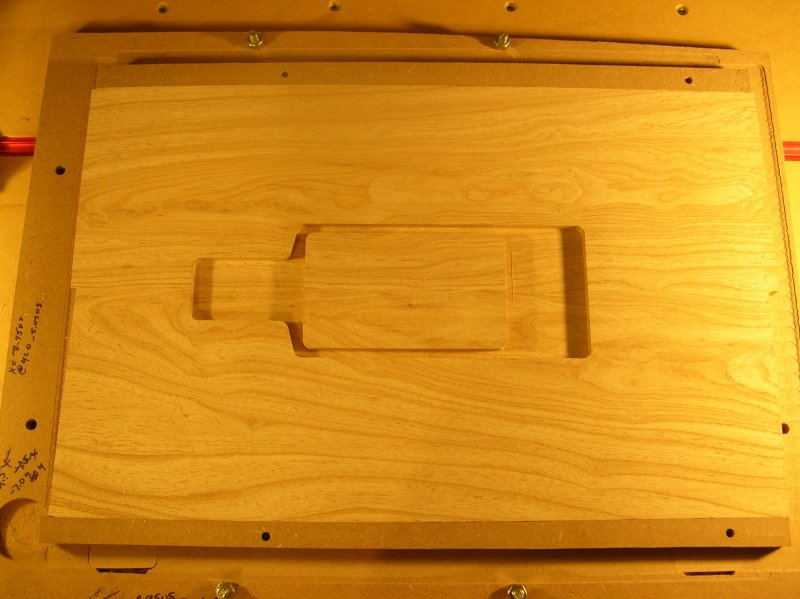

The top is made from a blank that's been planed to 1/2" thick. This one is southern ash. It is mounted bottom side up on the CNC. Here it is after cutting the block route.

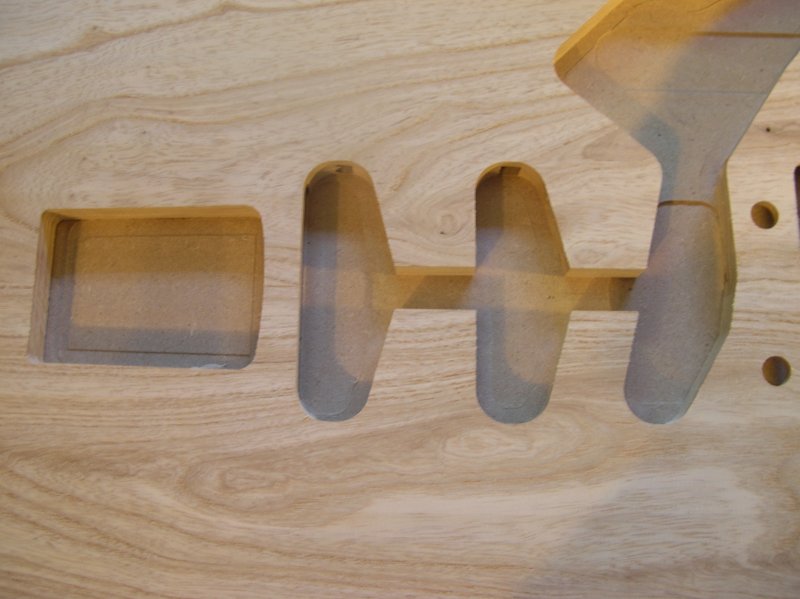

The top is then flipped over and the neck, pickup, control, jack, and tremolo stud routes are done in one step.

The forearm contour cuts through both the top and the bottom. Here is the forearm route in the top.

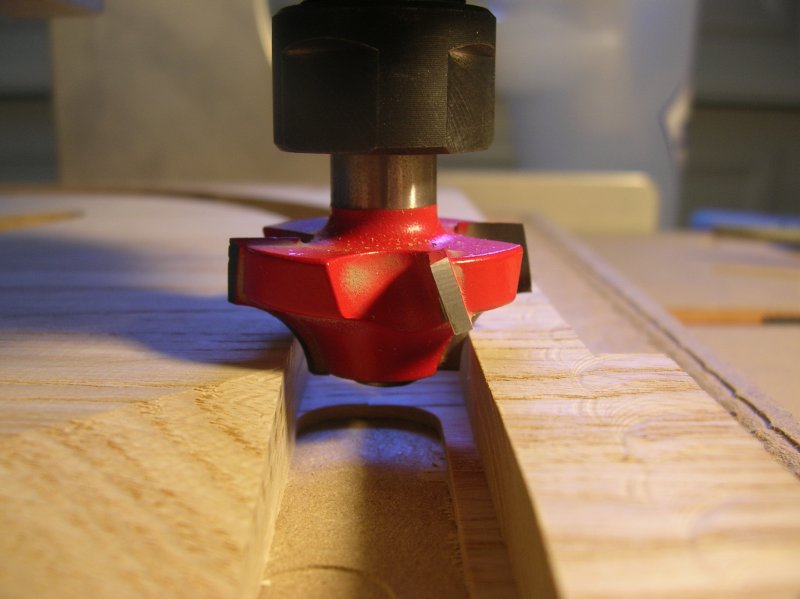

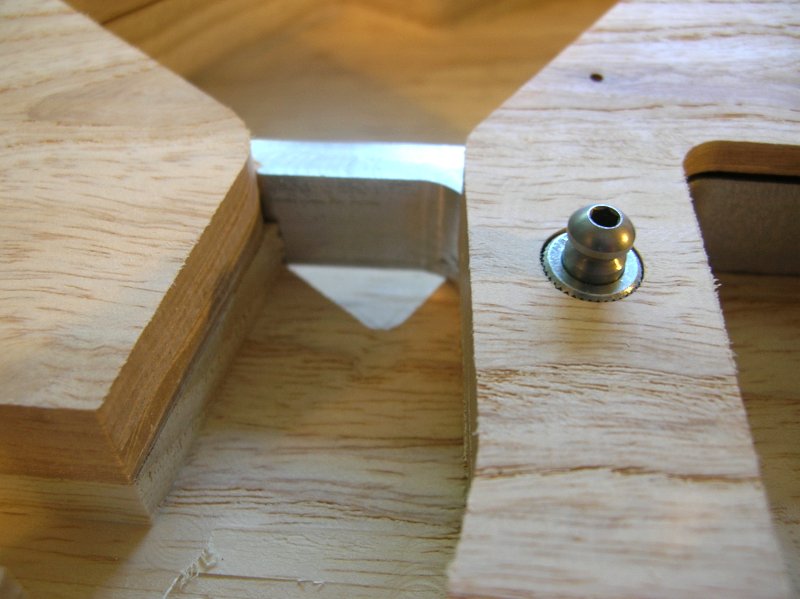

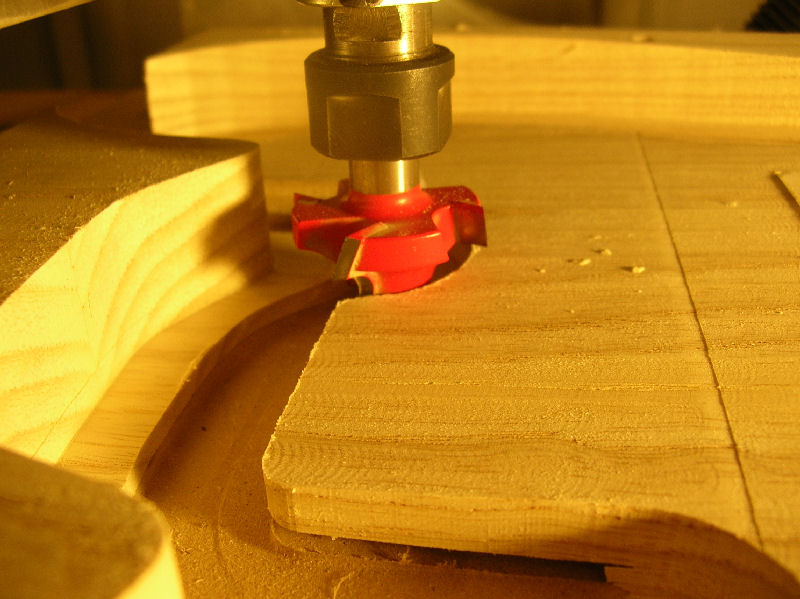

Now it needs the 3/8" roundover cut. This is done by cutting the bearing of a 3/8" roundover bit.

One quick cut around and it is done.

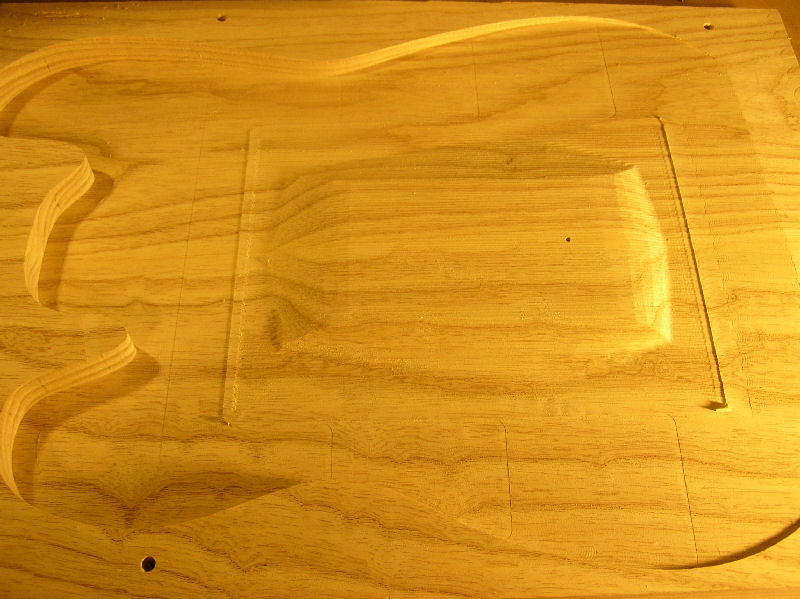

The bottom is made from a blank that's been planed to 1.25" thick. Here it is after cutting the block route.

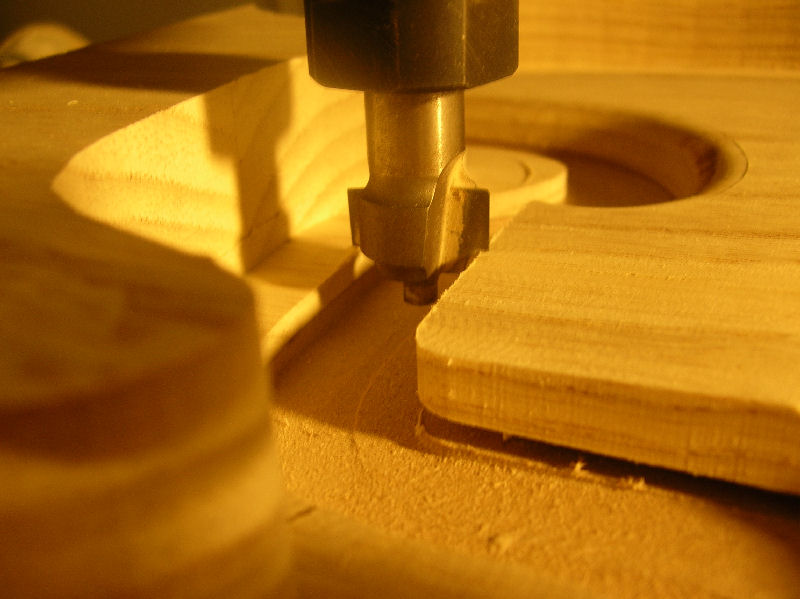

Then the neck, pickup, control, and jack routes.

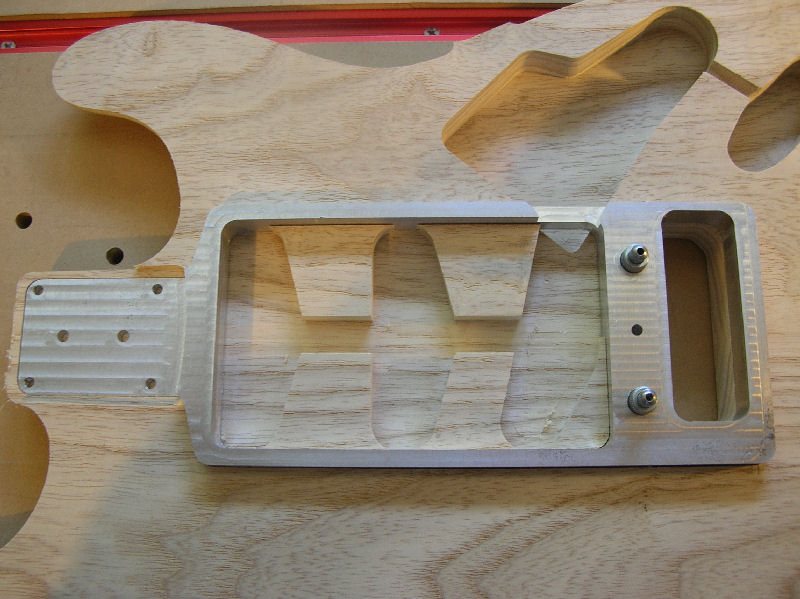

Here is the aluminum block sitting in its route.

The lower part of the forearm cut is then done.

Here is the body bottom, with the aluminum block and the finished top.

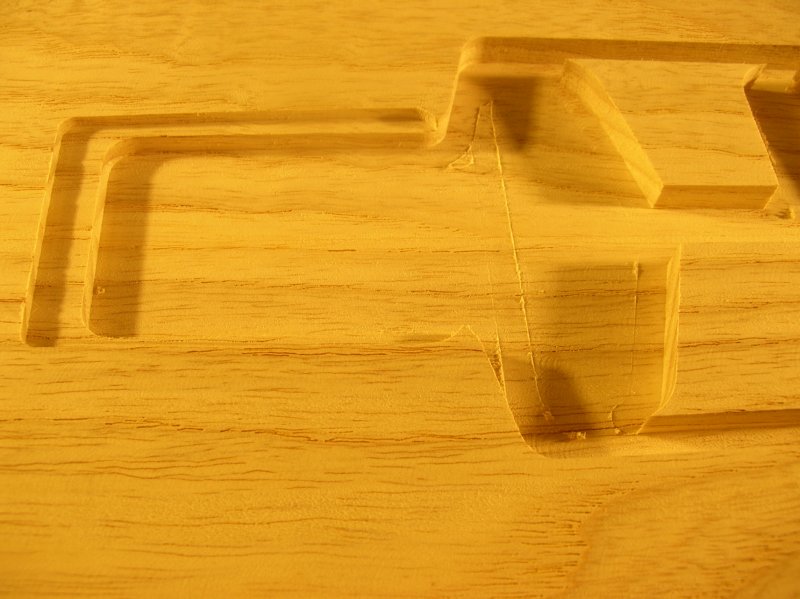

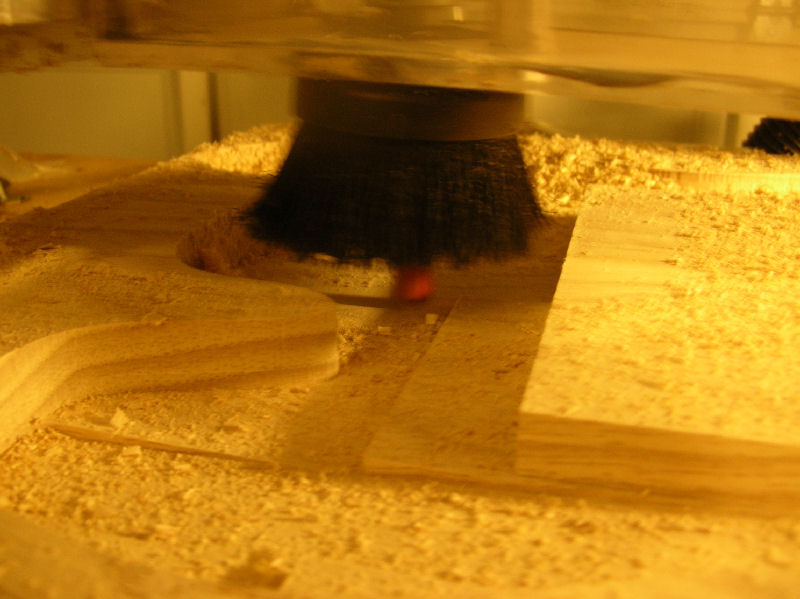

The bottom is the flipped over to the backside is facing up. The wedge angle is then cut into the backside. The recangular section in the center is for the bulge areathat fits the tremolo cavity. Here it is cutting the wedge route. Lots of wood chips here.

After the main wedge cut is done.

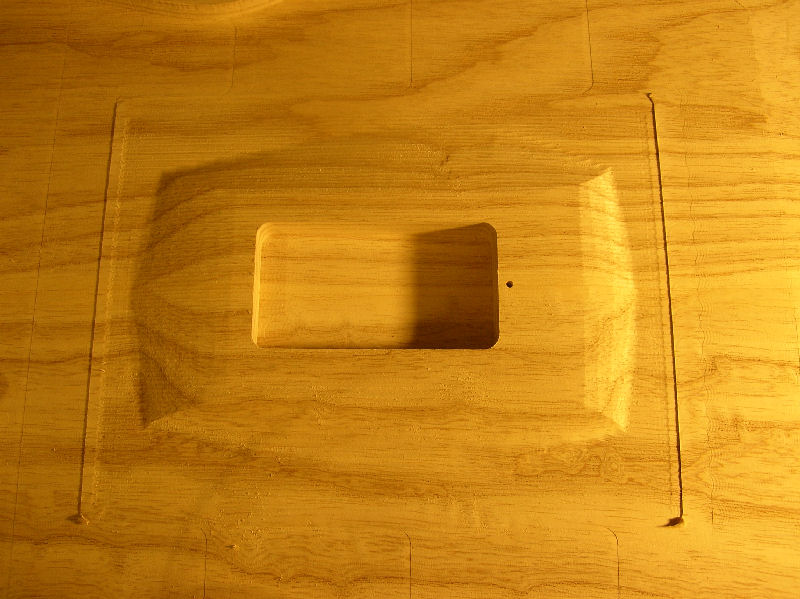

The tremolo cavity bulge is roughed with a 0.500" end mill.

And then fine cut with a 0.500 ball mill

The tremolo cavity and tremolo block cavity are then cut.

Then a thin area is routed such that the tremolo cover will be recessed into the bulge on the back of the body.

Like the body top, the 3/8" roundover is done on the CNC. Two pre cuts are done to make room for the 3/8" roundover bit which at its widest, is about 1.5" in diameter. Because of the wedge shape, the pre cuts actually cut into the waste board.

Setting the Z height on the roundover is critical. I usually error on the high side so it doesn't cut too deep.

Here is the bottom side of the body bottom after the 3/8" roundover is cut.

The area around the heel is cut with a 1/8" roundover bit.

The tummy cut is then done with a 0.500 ball mill.

Here is the body bottom after the roundover and tummy cuts.

The the final cut out is done with a 0.500" end mill. Notice the tabs holding it to the body blank.

The body bottom is then cut from the blank. Here is both sides.

The body bottom weights 1 lb, 15.4 oz.

The aluminum block with the tremolo studs weighs 12.2 oz.

And the body top weighs 1 lb, 4.6 oz.

The body top, aluminum bloack, and body bottom are glued together. This is what it looks like after rough sanding.

After sanding, the body weight just over 4 lbs.

|